Alternator Home Page

What is an alternator ?

|

What does an alternator do ?

|

The simple definition:

An Alternator is a device that converts mechanical energy to electrical energy.

Sounds simple enough, right?

So how does it really work?

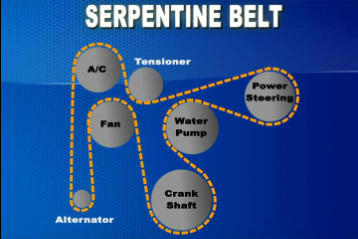

First, the cars engine provides the mechanical energy through a pulley attached to the engines crank shaft. As the engine runs the crank shaft pulley spins and drives a belt that transfers this spinning motion to the other pulleys that the belt contacts. On a typical modern car this includes pulleys attached to the alternator, the power steering pump, the water pump, and the air conditioning compressor. The alternator then uses this mechanical energy from the spinning pulley to produce electrical energy. The way in which the internal workings of the alternator are able to produce this electrical energy is where it gets somewhat more complex.

So how does it really work?

First, the cars engine provides the mechanical energy through a pulley attached to the engines crank shaft. As the engine runs the crank shaft pulley spins and drives a belt that transfers this spinning motion to the other pulleys that the belt contacts. On a typical modern car this includes pulleys attached to the alternator, the power steering pump, the water pump, and the air conditioning compressor. The alternator then uses this mechanical energy from the spinning pulley to produce electrical energy. The way in which the internal workings of the alternator are able to produce this electrical energy is where it gets somewhat more complex.

Now for what goes on inside the alternator.

( Non technical readers digest version....really )

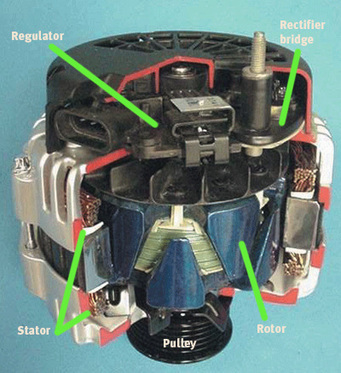

The alternator pulley is attached to the shaft of the alternator rotor. The rotor contains a wire coil which produces a magnetic field when a voltage is applied to the rotor coil via the voltage regulator and brush set. The rotor has pole pieces made of special metal that form magnetic north and south poles alternately (north-south-north-south and so on). The rotor spins inside a stationary set of coils called a stator. A rotating magnetic field ( with north and south lines of force ) spinning inside a stationary coil produces an alternating current in the stationary coil. That's all good and well but a cars electrical system requires direct current not alternating current. So the alternating current moves through the wire in the stator to a diode assembly called a rectifier. The rectifier assembly effectively converts the alternating current into direct current that can be used to maintain the state of charge of the battery and provide power to run the cars accessories. Since a fair amount of heat is generated at the rectifier from the process of converting from alternating current to direct current the alternators has fans that circulate air to help cool the internal components. **Keep in mind this is just a thumbnail sketch of the internal workings of an alternator. Some things have been simplified and others omitted in order to make it short and to the point. For a much more detailed description of alternator design and theory as well as many other interesting things click on the following words- TECHNICAL STUFF PAGE

What is the purpose of an alternator ?

An alternator is designed to maintain the state of charge of a cars battery while the car is being driven by providing the energy required to power the cars electrical system. That's it. Why is this important? Assuming the car has a good, fully charged battery, the voltage when you get into the car is around 12.6 volts. When the car is started the voltage is decreased slightly due to the energy draw of the starter. Furthermore, as you drive, electricity is being used by various components of the car. These include the ignition system, the computers, the radio, the lights, the air conditioning, the DVD player, the GPS navigation system, the power seats, the power window motors, the windshield wipers, the fuel pump, and many other accessories. That adds up to a lot of power. If the alternator was not present to provide that power it would come directly from the cars battery. It would take very little drive time to run the battery down to the point where the car would no longer run from the lack of electricity. Because the alternator is present and works to provide the power to run the cars electrical system this means the voltage of the battery when you finally reach your destination is still around 12.6 volts - the same as it was when you started driving. The alternator has maintained the state of charge of the battery and your car is ready to be started and driven again.

What are the limitations of the alternator ?

ALTERNATORS ARE NOT DESIGNED TO RECHARGE A LOW OR DEAD BATTERY !

Charging a dead or low battery is the job of plug in battery charger only!

As stated above an alternator is designed to maintain the state of charge of a battery. Due to the huge power requirements of the normal operation of a cars electrical system today the alternator usually runs at or near its maximum output the entire time the car is driven. A dead or low battery adds to the work the alternator is required to do. There simply is no way for the alternator to recharge a low or dead battery and power the electrical system at the same time.

Charging a dead or low battery is the job of plug in battery charger only!

As stated above an alternator is designed to maintain the state of charge of a battery. Due to the huge power requirements of the normal operation of a cars electrical system today the alternator usually runs at or near its maximum output the entire time the car is driven. A dead or low battery adds to the work the alternator is required to do. There simply is no way for the alternator to recharge a low or dead battery and power the electrical system at the same time.

Improvements in alternator design over the years.

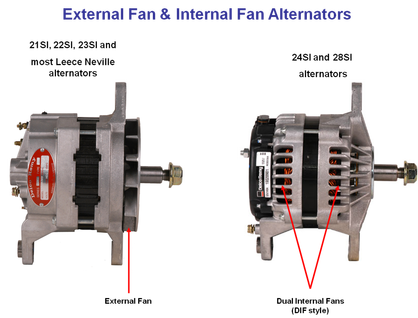

While it is correct to say that the basic principles of the alternator are the same today as they were when the first alternator was designed, many specifics of alternator design have changed considerably. The amount of energy required to run a cars electrical system today is about 3 times what it was in earlier cars. In the 1970's the typical maximum power output of an alternator for a fully loaded car was rated at about 55 to 60 amps. Today the typical maximum output rating is approaching 150-160 amps even though the alternators themselves are only slightly physically larger than their predecessors. This achievement of greatly increasing energy output while maintaining a relatively compact size and weight is impressive. Some alternator manufacturers have managed to do this while actually increasing the life span of the alternator. In order to accomplish this they have improved (1) fan designs for better cooling, (2) rectifier and regulator designs for increased durability,(3) and stator design to maximize the amount of wire that can be fit into the alternator. Modern alternators use 2 internal fans attached to the rotor to circulate air through the alternator. Another simple thing is that newer alternators spin at higher speeds than ever before. This means the fans can mover more air for cooling. This also helps increase overall output since part of an alternators energy output is a function of its how fast it spins. For more on this and other interesting things click on the following words.....TECHNICAL STUFF PAGE

|

ALTERNATORS

LAMPS BRUSHES ARMATURES BRUSH HOLDERS |

WINDOW REGULATORS

DIODES BEARINGS CLUTCH PULLEYS BATTERY ISOLATORS |

STARTERS

FUSES RELAYS SWITCHES SOLENOIDS |

WINDOW MOTORS

DRIVES BUSHINGS BATTERY CABLES VOLTAGE REGULATORS |

GENERATORS

BULBS ROTORS FIELD COILS WIRE SUPPLIES |